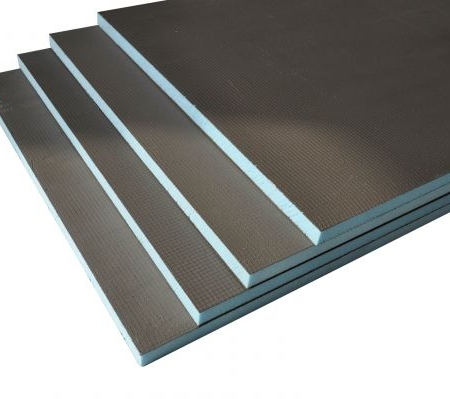

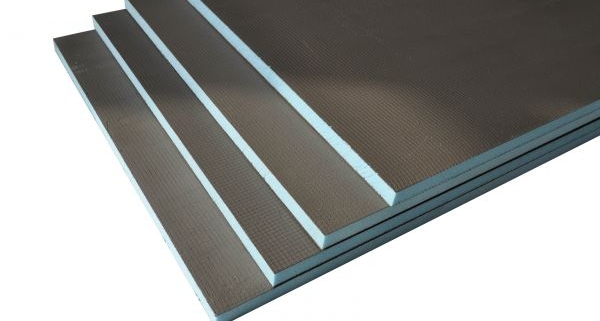

Thermasheet Backer Board (Exterior)

Full and half sheets available for Local collection from Canberra only.

Smaller boards can be shipped

Thermasheet is the perfect mosaic substrate

This specially manufactured cement polymer coated board gives the ideal surface to lay your tiles directly.

ThermaSheet is easy to use and can be fixed using cement based flexible tile adhesive – solvent based, or ready mixed adhesives MUST NOT be used. ThermaSheet provides a perfect surface on which to apply decorative finishes such as tiles, synthetic renders, decorative plaster etc.

It is light, strong, 100% waterproof and can be cut to any shape with a craft knife. It is inert, and will not warp, shrink or expand over time. Being waterproof it is suitable for exterior as well as interior use. It is virtually identical to wedi or marmox board, which is commonly used as a mosaic substrate in Europe and America. It is designed as a backing board for ceramic tiles in bathrooms, saunas and steamrooms.

Thermasheet has an extruded, polystyrene core and is covered in a fibreglass mesh and polymer-modified cement coating. The glass mesh adds strength and rigidity to the panel. The strength of ThermaSheet is in its complex composite construction. The closed cell structure means it has excellent properties for waterproofing both walls and floors, as well as insulating beneath underfloor heating.

Merlin Mosaica also supplies fixings that include special washers for protecting the surface, allowing bolts to secure D rings for a hanging mechanism. The D rings are rated at 12kgs each, so two of them can support a 24kg mosaic project. Instructions are supplied for attaching the fixings and preparing your board for a mosaic project.

Technical details

Thermasheet is made up of three components: high-density extruded blue polystyrene, fibreglass mesh, and an outer layer of polymerised mortar. It is inherently waterproof. The foam is extruded under enormous pressure, creating a dense mass of tiny, closed cells so tightly packed together that water cannot penetrate the insulation, nor can the insulating air escape from the cells. The foam is then covered with a glass fibre mesh to add strength and rigidity, which in turn is coated with a polymer-modified cement coating. The cement coating allows for adhesion as a bonding surface.

- Display 15 Products per page