Description

NOTE:

- This product cannot be combined with any other product in the same order (except the Dressing Stone). If you require other products, please place a separate order for them.

- Free Postage. Cannot be used with other discounts. I can advise the most cost effective option for you.

- Local Collection is not available on this product.

- Express postage cost will depend on your postcode. If required, please contact me for a quotation.

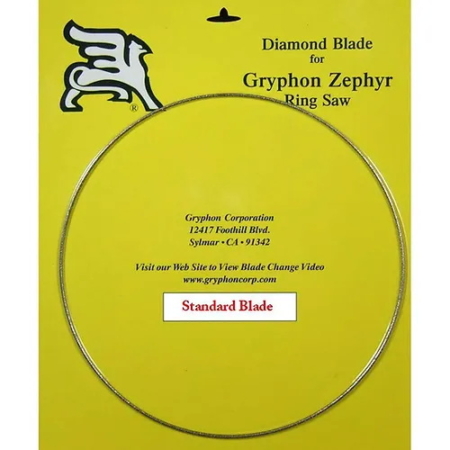

Gryphon Zephyr Ring Saw

The new Gryphon Zephyr Diamond Ring Saw offers advantages not found in other glass saws, and comes with a Spotlight for easy viewing:

- the round blade is omni-directional (can cut in any direction)

- operation is very smooth and quiet

- large work surface that is free of obstructions

- the overhead blade support is slender, allowing the artist to have a very clear view of the material as it is cut

- has a deeper throat and more clearance for the glass than other consumer glass saws

- has a secondary water reservoir for use in hand-held mode. Please read instruction manual carefully when converting between hand-held and platform modes.

- will cut glass, tile, rock and all other similar hard materials.

- Select the blade that is best suited to your current application

- When using other materials, it is advisable to clean the diamond blade with the Gryphon Dressing Stone.

- A separating blade that will allow you to make inside cuts without requiring a lead-in slot is also available. Merlin Mosaica is hoping to offer these in the near future.

- ships with a second blade and a set of guide wheel replacement rubber inserts

Special attention has been given to designing the saw for quiet operation and for low maintenance. The critical moving parts are shielded to minimize the abuse from the glass dust that is generated when cutting. The highest quality bearings and wheels are used to extend the life of these critical parts.

The motor/blade assembly is a separate unit that can be removed from the base and used as a hand-held saw. This is useful for cutting items that cannot easily be brought to the table. A small water reservoir is built into the blade assembly housing and will hold enough water for a few minutes of hand-held cutting. When the saw is used in the normal configuration (installed in the base), the base will hold enough water for several hours of cutting.

- Quiet operation

- Large 444mm square work surface

- 170mm throat clearance

- 138mm height clearance

- Long lasting bearings and wheels

- Water Level clearly marked

- When used as hand held, not necessary to attach separate housing cover

- Convenient finger grip for hand held operation

- Australian compliant plug, 240v

- Plug is suitable for Australia AND New Zealand

- 12 month Warranty

Note:

- Always use with the face shield installed. It acts to hold the blade casing together firmly. Flip up if you prefer not to use it.

- Let the saw do the work and do not force or put pressure on the glass as you are cutting, as this exerts pressure on the blade, and you may experience more frequent blade breakages.

- The water reservoir should be emptied when not in use.

- If in a hard water area, consider using distilled water.

How to install the Cutting Surface:

Frequently Asked Questions

I’m having trouble putting the work surface on. What’s the secret?

The work surface is designed to fit tightly so that it will not rattle. The surface is easy to install once you know the technique. To install the work surface, put it in place starting with the left rear corner. Fit the left rear corner into the slot running around the base. Next, take your right thumb and push the right side of the platform towards the centre of the saw and down. You will hear it snap into place.

What is the best way to mark the pattern before I cut?

As you undoubtedly have or will discover, the glass gets wet when you use a diamond saw. For this reason regular markers, such as Sharpies, quickly wash away. There are markers available that use paint rather than ink, and these are well suited for marking patterns on glass. The most popular of these seems to be the Pilot Extra Fine Gold and Silver Creative Marker. You can also copy your pattern onto overhead transparency material and glue or tape the pattern to the glass. In a pinch, you can use Chap Stick or Vaseline over your pattern.

Should I be taking any precautions when I don’t plan to use the saw for awhile?

We recommend that after using the saw you empty the base, add some clean water, and run it for a few seconds. This will help to rinse out the glass dust that was in the dirty water and has accumulated on the inner workings. Emptying the base of the new water is a good idea if the saw will be sitting for a while, as the lowest pulley inside the saw would otherwise be sitting in water.

How do you change the blade?

What is a Separating Blade?

A Separating Blade allows you to make inside cuts without a lead-in. Watch this video for a short demonstration of using the Separating Blade.

What sort of preventive maintenance should I be doing?

- Open the covers and inspect the working parts on a regular basis.

- Clean out any sediment that has accumulated, rinse the inside with fresh water, and inspect the rubber wheel inserts for wear.

- When you notice that the rubber has worn enough so that it doesn’t hold the blade from moving from side to side, you should replace them.

- The residue from some of the materials that you will cut is much more abrasive than others, and after a few inspections you will have a good idea of how often to inspect and clean your saw.

You can often extend the life of the blade when cutting speed diminishes by cutting a small section of a dressing stone, or alternately any hard gemstone or garden stone. This will help flush the softer material from the blade and sharpen the diamonds. Also, this is a good technique for removing burrs from the blade if you find that you are getting chipping in your glass.

How do I prevent small pieces of glass from falling through the blade hole in the work surface?

If you are trimming your piece and having trouble with the very small scrap falling through the worksurface, you can cut a small square piece of tape, such as electrical tape, to cover the hole. Cut a slit from the middle of one side to the centre of the square so that you can install the tape around the blade. If you prefer, you can buy ready cut tape.

Reviews

There are no reviews yet.